Yves right here. This manufacturing unit constructing pattern, sighted by Wolf Richter, bears watching. It’s a concrete demonstration (pun supposed) that there’s a critical effort underway to “reshore” manufacturing. Nevertheless, want and spending don’t essentially translate into outcomes. Recall the nice hyped Foxconn manufacturing unit in Wisconsin, the place they sucked a lot of subsidies out of the state after which punted. From CNBC in 2021:

Taiwan electronics producer Foxconn is drastically scaling again a deliberate $10 billion manufacturing unit in Wisconsin.

Underneath a deal, Foxconn will cut back its deliberate funding to $672 million from $10 billion, and slash the variety of new jobs to 1,454 from 13,000.

And bear in mind, that is a longtime participant, as in Foxconn is aware of how one can begin up and function factories. This isn’t Individuals who is likely to be scrambling to search out desperately wanted manufacturing unit flooring supervisors and better stage manufacturing managers.

Wisconsin did a minimum of restructure the deal and clawed again plenty of the subsidy commitments.

Equally, Alexander Mercouris has reported lengthy type on the failed US effort to extend 155 mm shell manufacturing. Along with many mishaps which he recounted lengthy type, the bottleneck stays a scarcity of gunpowder. There appears to be just one manufacturing unit, in Poland, that makes TNT. The US had determined to maneuver off TNT as a result of environmentally nasty, however the replacements by no means labored (unsure as a result of they failed as explosives or have been too arduous to provide at scale and/or affordable price).

Admittedly, it’s a considerably totally different kind of producing, however I used to be a paper mill brat and my father ran paper mills. Coated paper may be very fussy. The coating, in his day mineral clay, is utilized when the paper is moist. The paper machines need to function at very high-quality tolerances or else the paper breaks, inflicting expensive downtime.

The mills need to run 24/7 apart from scheduled upkeep as a result of the capital prices are excessive.

My father ran startups and turnarounds as a result of hardly anybody within the trade may execute them. He finally grew to become the top of producing at one of many main papermakers.

The rule of thumb was a profitable startup (of a single “machine” as in manufacturing line, which price ~$500 million in Nineteen Seventies) took two years and price 20% of the capital prices. An unsuccessful startup was a working cash sore.

In different phrases, erecting manufacturing unit buildings is the simple half. Keep tuned as to how excessive the profitable opening and manufacturing charge is.

By Wolf Richter, editor at Wolf Avenue. Initially printed at Wolf Avenue

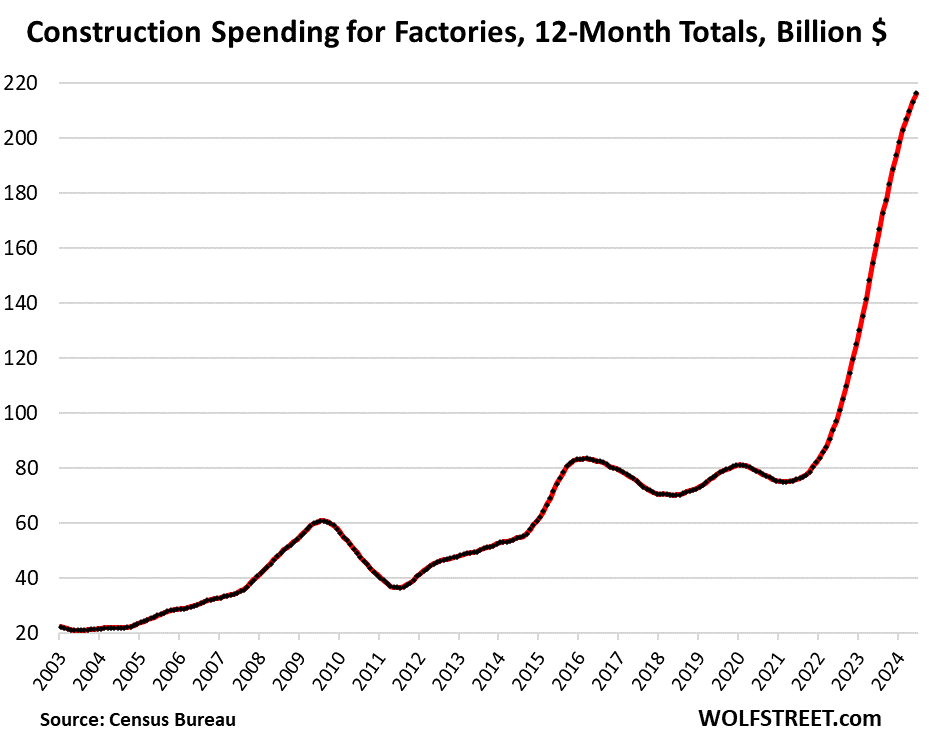

Corporations invested a report $19.7 billion in June within the development of producing services, up by 18.6% from the already surging ranges in June 2023, up by practically 100% from June 2022, and up by 209% from June 2019, in keeping with the Census Bureau as we speak.

The funding totals right here solely cowl the precise development prices of the services, not the prices of the manufacturing tools and set up that may dwarf the development prices of the constructing. The full price of an enormous chip plant would possibly attain $20 billion, however the development prices are the smallest a part of it. So the entire quantities invested in manufacturing crops, together with the tools and set up, are a lot larger. However right here, the quantities solely check with the development of the crops, and will be seen as a directional indicator of complete funding in manufacturing.

Along with the development growth of semiconductor crops, numerous different manufacturing crops have been introduced, and proceed to be introduced.

The explosion in manufacturing unit development that began within the second half of 2021 was one of many modifications that got here out of the pandemic when America’s scary dependence on China grew to become obvious in large shortages of all types of products, together with semiconductor shortages, and unbelievable supply-chain and transportation chaos, that precipitated company America and coverage makers to rethink the technique of infinite globalization.

The CHIPS Act, signed into regulation in August 2022, was a part of the motion. Whereas the primary awards have been introduced, there’s a lot of stuff left to do, together with due diligence, and the money hasn’t been disbursed but. That’s nonetheless to come back.

The 12-month complete of funding in manufacturing crops jumped to $235.5 billion, up by 19% from the identical interval a yr in the past, up by 100% from two years in the past, and up by 217% from the identical interval in 2019.

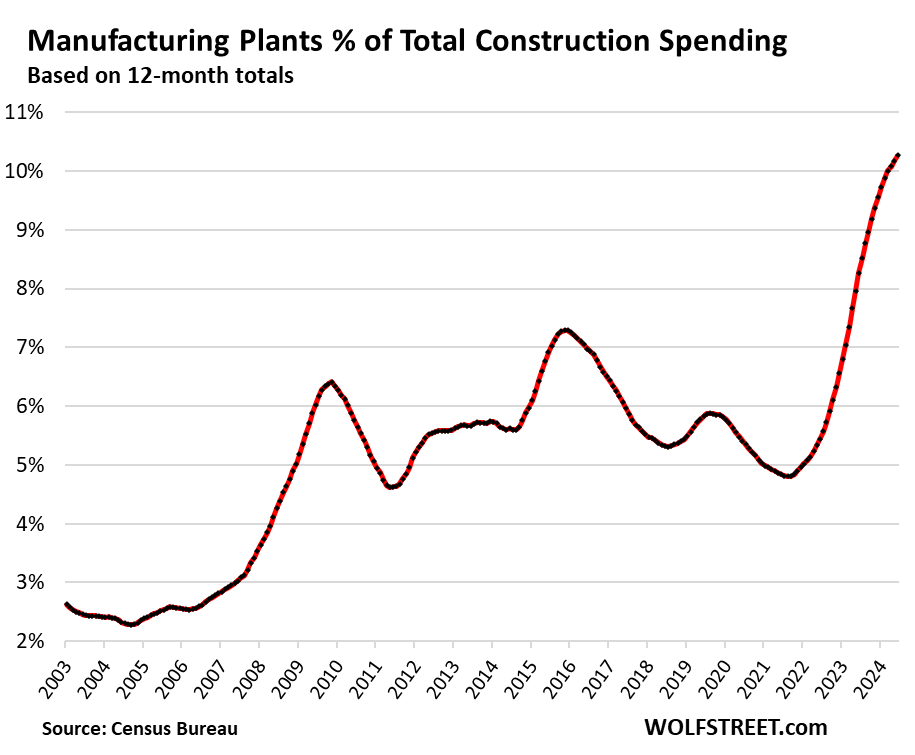

Building spending on manufacturing services now accounts for over 10% of complete development spending within the US, residential and non-residential, from single-family homes to roads and energy crops.

It’s all based mostly on the precept that industrial robots price the identical within the US and China, that guide labor is a a lot smaller price element in trendy automated manufacturing, and that transportation prices (which spiked in the course of the pandemic) and lack of Mental Property (IP), which is a given in China, and different dangers need to be added to price equation.

As well as, the more and more sophisticated and burdened relationship between the US and China has uncovered for all to see that the reckless dependence by US firms on manufacturing in China is a basic threat, not just for the businesses, but additionally for nationwide safety.

Nobody goes to construct a manufacturing unit within the US to make low-value merchandise, akin to T-shirts. It’s all centered on sophisticated high-value merchandise, akin to motor autos, chips, electrical and digital merchandise, heavy elements and tools, and so on.

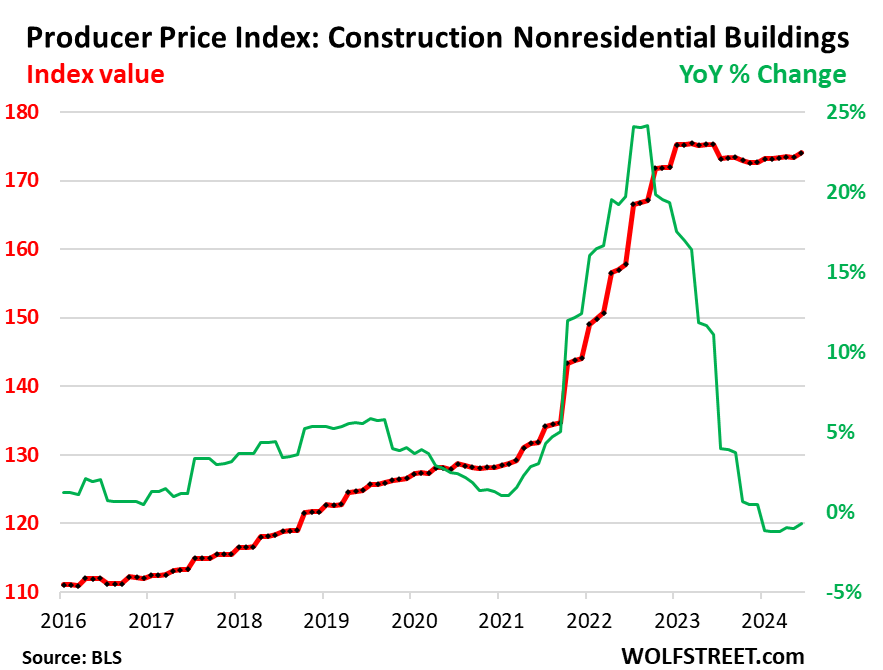

Inflation in Building Has Abated

The Producer Value Index for development prices of nonresidential buildings, after blowing out in mid-2021 by way of 2022, began plateauing in early 2023 and has remained roughly unchanged since then (purple within the chart beneath).

On a year-over-year foundation, the PPI for nonresidential development has been flat to barely adverse since late 2023, after having spiked by as a lot as 24% in mid-2022 (inexperienced).